Drill bits – good acquaintance in many households

Almost every do-it-yourselfer has worked with them: the classic drilling tools for cordless screwdrivers, drills, impact drills or hammer drills. The twist drills consist of the drill shank, chip-removing grooves and the drill tip. Decisive for the application of the drill is not only the material, but also the cutting geometry, the rake angle and the spiral angle, the so-called twist.

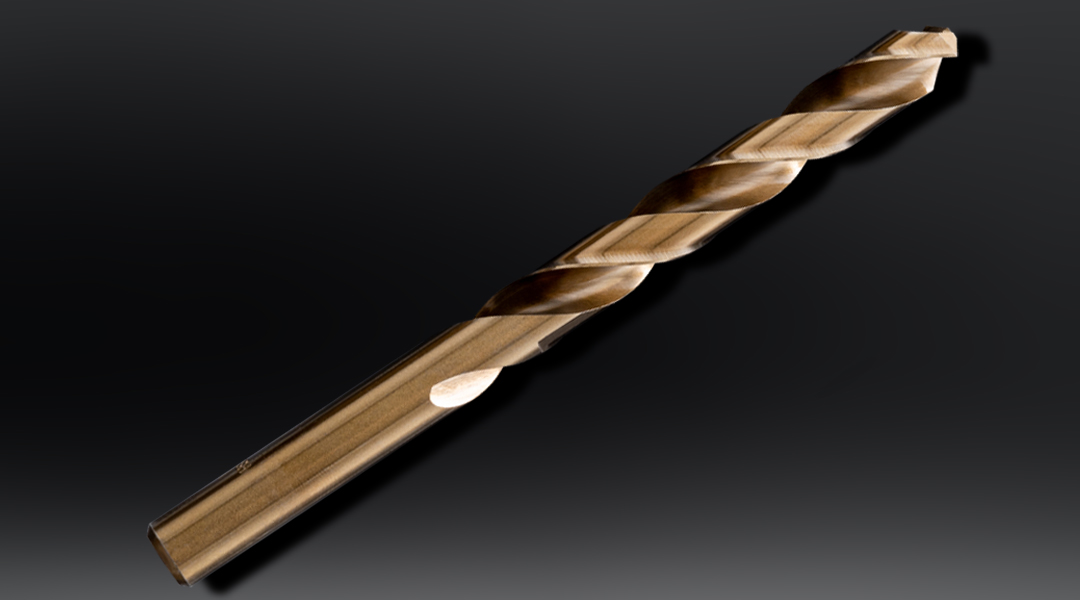

HSS twist drills leave even high temperatures cold

The high-alloy tool steel HSS can operate at up to four times higher cutting speeds than ordinary tool steel. It retains its hardness up to around 600 °C. In practice, HSS twist drills are used in different qualities. They are all characterized by:

- Temperature resistance

- Wear resistance

- Heat hardness

- Cutting edge stability

Thus, twist drills made of high-performance HSS high-speed steel are also able to cope with many material requirements. Accurate work and long-term cost savings are added to this.

Are you looking for the right drill for your specific application? Please feel free to contact us.

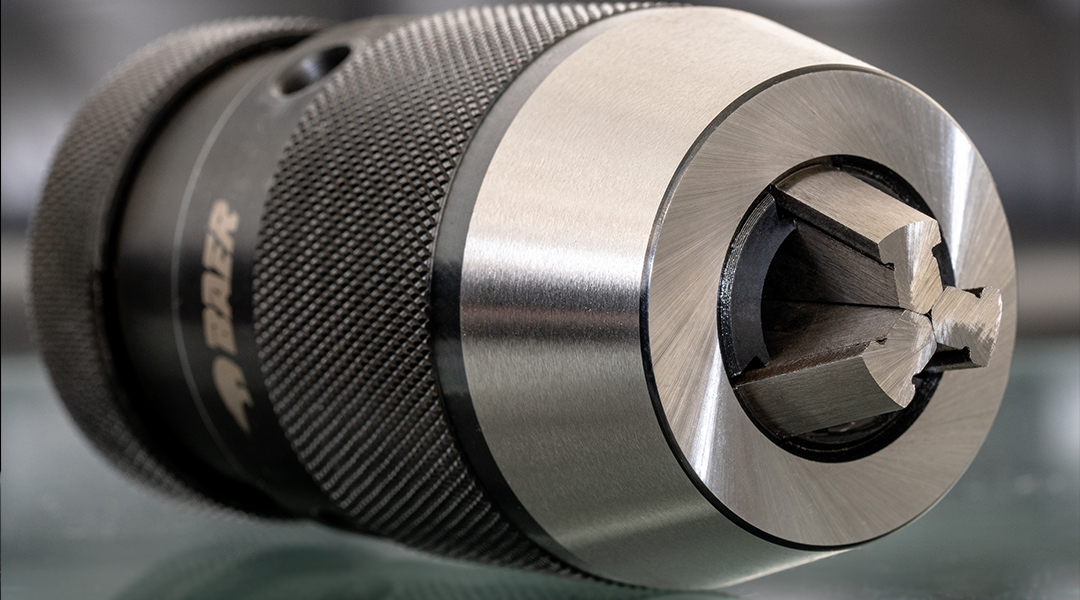

Twist drills from BAER - safe and competent

You need a twist drill? You'll find it with us - that's a promise! As a family business with more than 40 years of experience, we will be happy to advise you on twist drills & Co. You will find innovative products with the best quality - including continuous quality controls. We from BAER work with great expertise and passion on the further development of our products.

As our customer, you can always rely on our wealth of experience. Our more than 10,000 products are held in high esteem - even worldwide. Of course, we guarantee fair prices and short delivery times. Simply contact us - we will be happy to help you immediately.

What is a twist drill and what is it used for?

A twist drill, also known as a spiral drill or spiral flute drill, is a tool that can be used to drill holes in materials such as steel, metal, plastic, concrete and wood. Their spiral cutting edge sets them apart from other drills. This particular cutting edge allows them to cut material and create holes.

What should you know in principle - we will be happy to explain it to you! Twist drills are basically divided into three types of tools - they are standardized in DIN 1414-1/2: Type N, which refers to normal-hard materials, for example steel; Type H for hard as well as tough-hard as well as brittle materials, for example high-strength steel, magnesium as well as plastics as well as Type W for soft as well as tough materials, for example aluminum, copper as well as zinc. They differ in terms of the size of the helix angle and often also the point angle.

Type N twist drills usually have a twist angle of 30 to 40 degrees and a point angle of 118 degrees. Type H twist drills have a smaller twist angle (13 to 19 degrees) and a point angle of 118 to 130 degrees. Type W twist drills have a larger twist angle (40 to 47 degrees) and a point angle of 130 degrees.

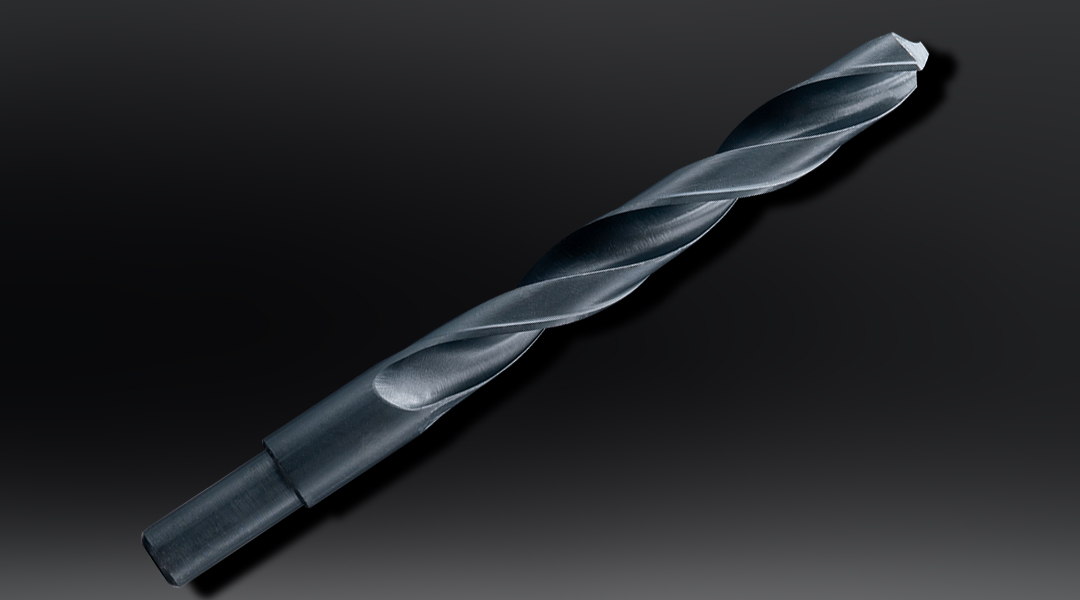

Twist drills according to DIN 338 are short and have a cylindrical shank. DIN 338 specifies the tolerances of the shank, the length of the shank, the total length and the length of the spiral flutes. The great advantage of standardized tools is that the machines can be set up more quickly and the user can be sure that the twist drill will always fit.

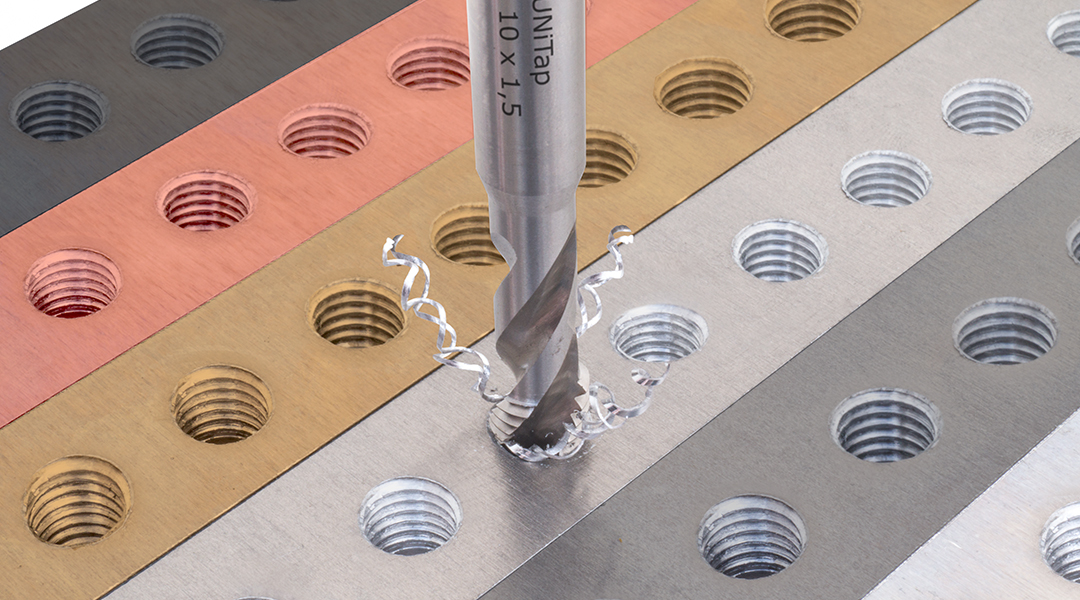

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.

Twist drills from BAER - always a good choice!

There's no question about it: twist drills are among the most widely used tools in metalworking, woodworking and stonemasonry. In addition, they are mainly used in the automotive and aircraft industries as well as in medical technology, shipbuilding and the electronics industry.

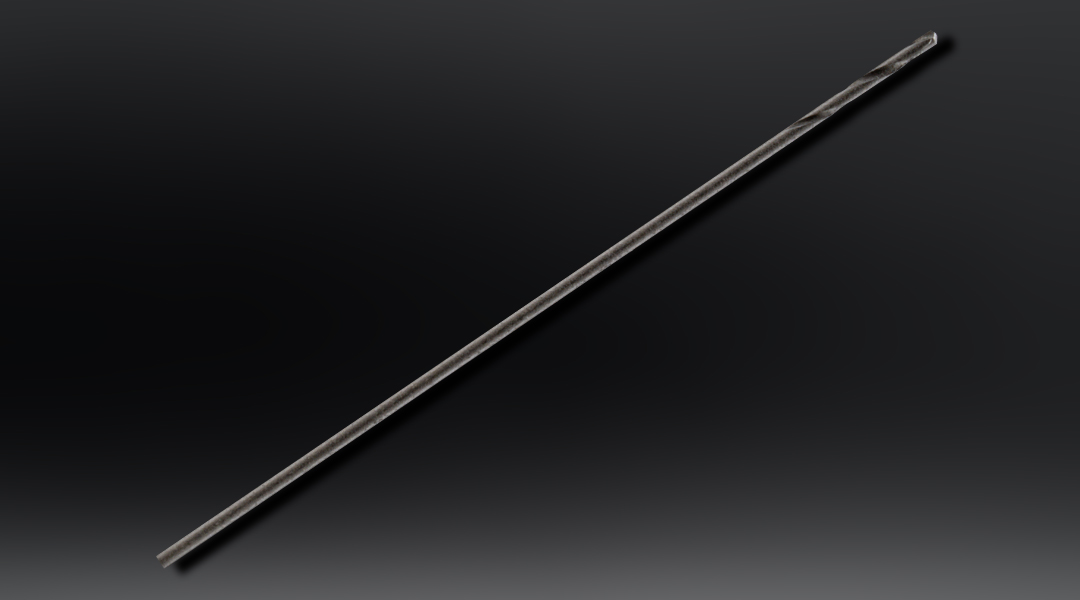

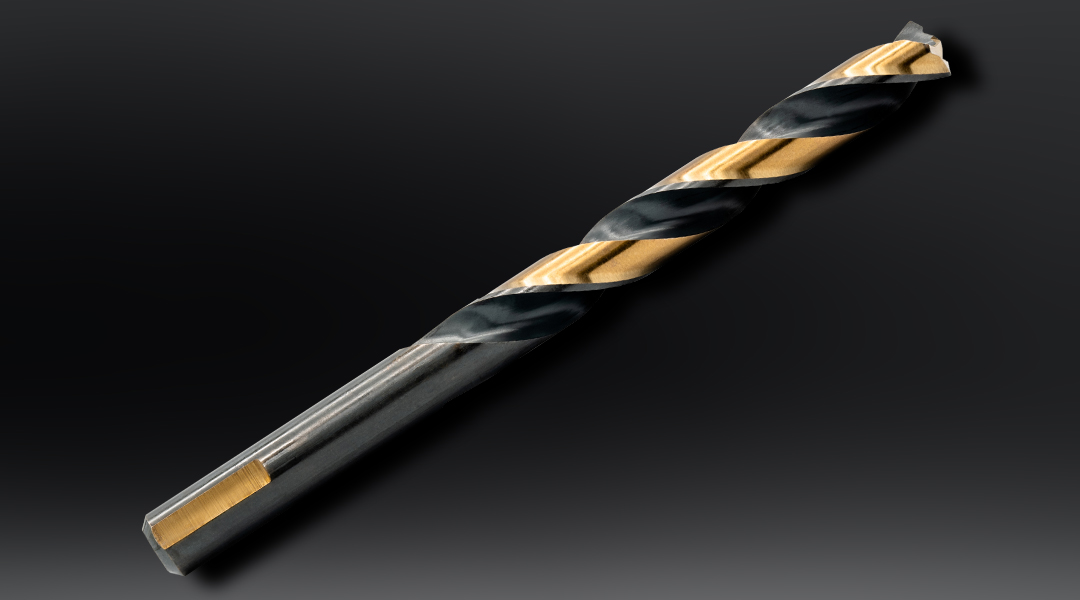

We offer special twist drills. These include concrete and stone drills, wood drills as well as SDS-Plus hammer drills, HSSE power drills, HSS and HSSE twist drills each with reduced shank as well as HSSG mini twist drills and still the HSSE extreme drills. These drills meet special needs. The technical terms SDS, HSS, HSSE and HSSG alone refer to various drill shank systems for percussive as well as rotary power tools, such as drills and rotary hammers. SDS stands for "plug-in rotary seat" and was originally developed by Bosch, later further developed with the designation "clamping by system". HSS means "High Speed Steel", i.e. the basic material is made of High Speed Steel. Additional letters beyond the designation HSS, for example HSSG, refer to the shaping process or the production. Accordingly, HSSG designates ground drills, with the "G" standing for ground. The focus is on the "HSSE extreme twist drill with cobalt alloy" - it is predestined for machining high-strength materials as well as stainless steels, we stock it with a diameter of 0.30 mm to 13.50 mm.

Particularly recommended is the so-called "HSSE Power twist drill set with three-surface shank" (for all materials), in which all common sizes (1 mm to 13 mm diameter) are included. These power twist drills can be used to drill uniform holes with pinpoint accuracy - the special feature - without having to pre-drill. The holes prove to be very clean - no burr on the edge of the hole. This 19-piece set belongs to the absolute top class and is suitable for various applications, for example, high-strength materials, stainless steels, heat-, rust- and acid-resistant steel, carbon steel, alloy steel, aluminum alloy, non-ferrous metals, iron, plastic plates, cast materials, tool steel, bronzes, copper and and and.

Not to forget the "power drills with triangular shank" from the house BAER. With the triangular shank, slipping of the drill can be avoided. Twist drills from 4.0 mm diameter benefit enormously from these additional clamping surfaces. This is ideally suited for hand-held cordless drills. The lower power consumption even protects the battery.

Please visit also our other websites

What makes a good twist drill?

Twist drills are available with different cutting edges, for example, two- or multi-blade cutting edges, which are used for drilling various holes in soft metals and also wood, twist drills with center point, which are used for drilling various holes with greater precision and less risk of slipping. Not to be forgotten are also so-called deep hole drills, which are used for drilling holes with a relatively large diameter.

The choice of the right drill tip profile appears to be important. Different profiles exist, for example, the conical tip, which is suitable for the majority of materials, in addition to the round tip, which is more suitable for soft materials, as well as the triangular tip, which in turn is more suitable for abrasive and hard materials.

Speaking of HSS twist drills or twist drills HSS, these twist drills represent a kind of cutting tool - they are used for drilling various holes in different materials. They are made of high-speed steel (HSS) and have a spiral profile that removes chips from holes as they are drilled. These drills are often used in handheld cordless drills, but also in drilling machines as well as CNC machines.

Precise and careful drilling with twist drills from BAER

One of the most important properties of twist drills is their ability to create holes without damaging or deforming the material. This is ensured by the spiral cutting edge - the latter removes the material in tiny spirals. This type of removal therefore prevents the material from being crushed or torn. Thus, it becomes possible to use twist drills to create holes with fairly smooth walls as well as precise dimensions. For many applications this is of crucial importance.

The correct handling of twist drills is crucial

There is also no question: If the performance and service life of twist drills are to be guaranteed, they must be sharpened or replaced at regular intervals. It seems important that they are properly clamped and also cooled - in this way damage can be avoided and precise drilling can be ensured. When drilling with twist drills, the right speed as well as the right material being drilled are considered crucial. If the speed is too high, the drill can overheat and be damaged. On the other hand, too low a speed can result in damage to the material as well as an inaccurately drilled hole.

Another important criterion of twist drills is cooling. During the drilling process, heat and pressure build up via the twist drill, which can damage the drill or compromise an otherwise high-quality hole. These problems can be eliminated with proper cooling of the twist drill. Various types of cooling are available on the market. These include lubricants and air or water jets.

Safety also proves to be of vital importance when using twist drills. Using the right technique is just as important as ensuring proper clamping and cooling. This also helps to prevent injuries and achieve highly accurate drilling. Don't forget to wear protective equipment, such as eye and ear protection.

Wide range of applications for the twist drills from BAER

Twist drills are considered an important part of the tool assortment - both for professionals and DIY enthusiasts. They are available in numerous different sizes as well as materials and different functions. This allows the drills to be used effectively for many different tasks. You can conveniently buy a large selection of sets and assortments for twist drills at BAER at Online-Shop.