Cooling lubricants (KSS) are an efficient and economical solution to maintain your tool. Adding a lubricant during machining operations reduces temperature, which in turn increases tool life. It also reduces friction between the tool and the workpiece, which in turn reduces wear.

These lubricants are particularly important in industrial manufacturing processes. However, lubrication is often underestimated, especially in thread cutting. Cooling lubricants such as cutting oil or cutting paste (for stainless steel) cool the machine tap and extend the life of the tool. Particularly in the case of coated taps, the lubricants cause the coating to adhere to the tap longer.

Cutting pastes and cutting oils from BAER are well suited for all types of steel and stainless steel and for all types of machining operations such as drilling, forming, tapping, turning, core drilling and sawing without leaving stains.

Cutting oil - tasks of cooling lubricants

As cooling lubricants, cutting oil and cutting paste are multi-component mixtures that are used primarily for two tasks: they are intended to lubricate and thus cool both the tools and the workpieces during machining.

Water is also used for cooling, but it is not effective enough in manufacturing because it is not capable of lubrication and thus does not have the ability to reduce friction and wear. Therefore, MWFs are the ideal choice to protect tools and workpieces.

They also enable effective removal of materials from the machining area, such as chips, and protect the machine, tool and workpiece from corrosion. These lubricants are also capable of preventing deposits through good wetting and flushing properties, thus protecting the machine from contamination and microbiological contamination.

Water-miscible and non-water-miscible cooling lubricants

MWFs are divided into different groups, depending on their water content. In general, there are water-miscible and non-water-miscible cooling lubricants. While the non-water-miscible grades usually consist of higher proportions of alloyed or unalloyed oils and are used pure, water-miscible cooling lubricants are generally more than 90% water.

Non-water-miscible cooling lubricants are mainly used in machining processes with high speeds.

Here is how they differ:

- non-water-miscible coolants are ready-to-use ("cutting oil" or ready-to-use emulsions)

- water-miscible coolants are available as concentrates and must be mixed with water before use ("emulsion")

Composition of cooling lubricants

- Cooling lubricant emulsions consist of oil and water, supplemented by emulsifiers and additives which adapt the properties of the emulsion to the particular application.

- Cooling lubricant solutions are usually free of mineral oil and synthetic. They consist of polymers and salts that are dissolved in water, while no additional emulsifiers are needed for distribution. Cooling lubricant solutions are often used in grinding because they are transparent and thus ensure a good field of view of the grinding pattern.

Advantages and risks of cooling lubricants

These lubricants have many advantages:

In addition to a very good cooling effect of the water, water-miscible cooling lubricants also contain emulsifiers, corrosion protection additives and biologically stabilizing additives that improve the lubrication and stability of the concentrate.

In addition, they are relatively economical compared to other cooling lubricants, as usually only about 10% concentrate is needed. Users of water-miscible cooling lubricants therefore benefit from a higher degree of process stabilization and less maintenance.

However, you also have to be aware of some risks when handling coolants:

- Water-miscible cooling lubricants have only a low lubricating effect due to their low oil content, and the cutting surfaces are poorly wetted.

- Microorganisms appear more frequently when water-miscible cooling lubricants are used, while non-water-miscible cooling lubricants are rarely affected unless they are not carefully handled and maintained.

- Germ infestation can cause serious health problems if it comes into contact with the skin. For tools and machines, germ infestation means, in the worst case, discoloration of the machined objects, shorter tool life and corrosion.

Our tip: To minimize the risk, you should store these lubricants frost-free and away from direct sunlight and heat. If necessary, you can add biocides or other stabilizing additives to the used emulsion to extend service life while improving worker protection.

Also be sure to dispose of the products properly

Cooling lubricants have a limited shelf life and must therefore be replaced occasionally when they absorb unwanted contaminants. They are subject to strict regulations and must therefore be disposed of properly by approved waste disposal companies or a licensed transporter. The waste consignment bill constitutes proof of the proper disposal of the cooling lubricants.

Cutting paste and other cooling lubricants from the professional

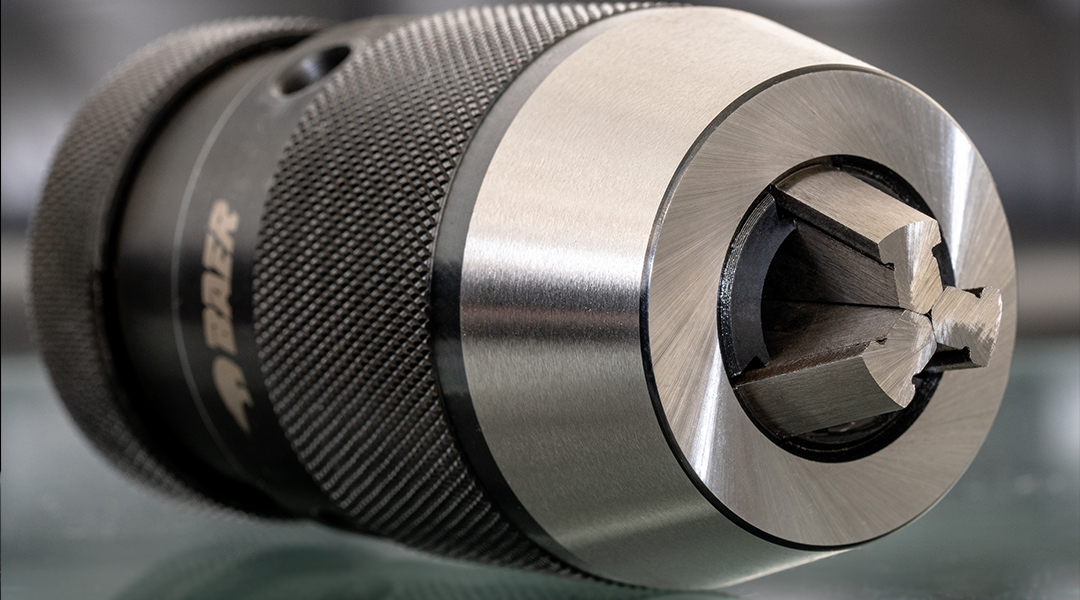

For efficient and economical work, we recommend the use of our high-quality BAER cutting pastes and cutting oils. These products are suitable for all steels and stainless steels as well as for all metal-cutting processing operations such as with the tap, die, saw or also twist drill.

Our high quality cutting pastes and lubricants are usually applied undiluted and do not use components such as chlorine, petroleum or sulfur in the cutting paste. In addition, they do not leave a greasy film on the workpiece.

What should you consider when choosing the right cooling lubricant? To ensure that you choose the right product, you should consider four points in particular:

- The type of manufacturing process used

- The cutting speed of the tool cutting edge

- The material to be machined

- The type and amount of lubrication and cooling required

Do you need advice or help with the individual selection of the right cooling lubricants? We will be happy to provide you with personal advice before you make your purchase.

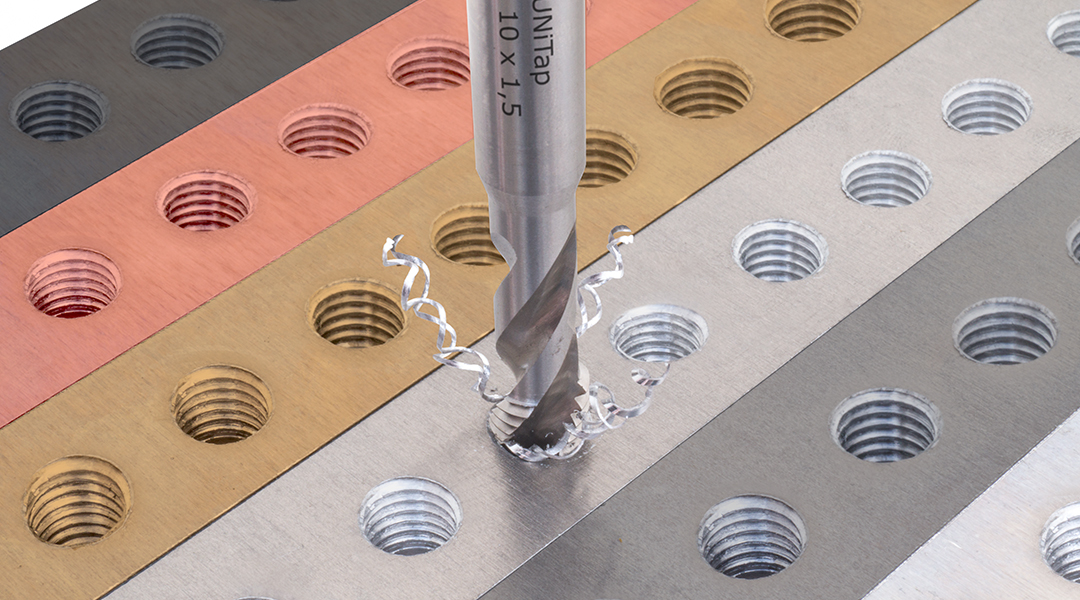

BAER-UNI products- All-rounder threading tools for best results

The UNI products from BAER are characterized by their universal application possibilities and, at the same time, long service lives. We have developed material structures, geometries and coatings especially with our customers in order to produce threads flexibly and efficiently.