Mini tap for watches, jewelry or precision mechanics

For a long time, the field of precision mechanics was almost exclusively reserved for watchmakers. There were no other tools that required such delicate work. Then came the 20th century with its rapid technical progress and precision mechanics suddenly became everywhere.

Microelectronics in particular has become an indispensable part of our everyday lives. After all, we've all been walking around for quite a while with little supercomputers in our pockets that are full of complex parts. Many components have to make do with little space and be securely installed. This is done by means of tiny screws. And where there are tiny screws - sure - there need to be tiny threads.

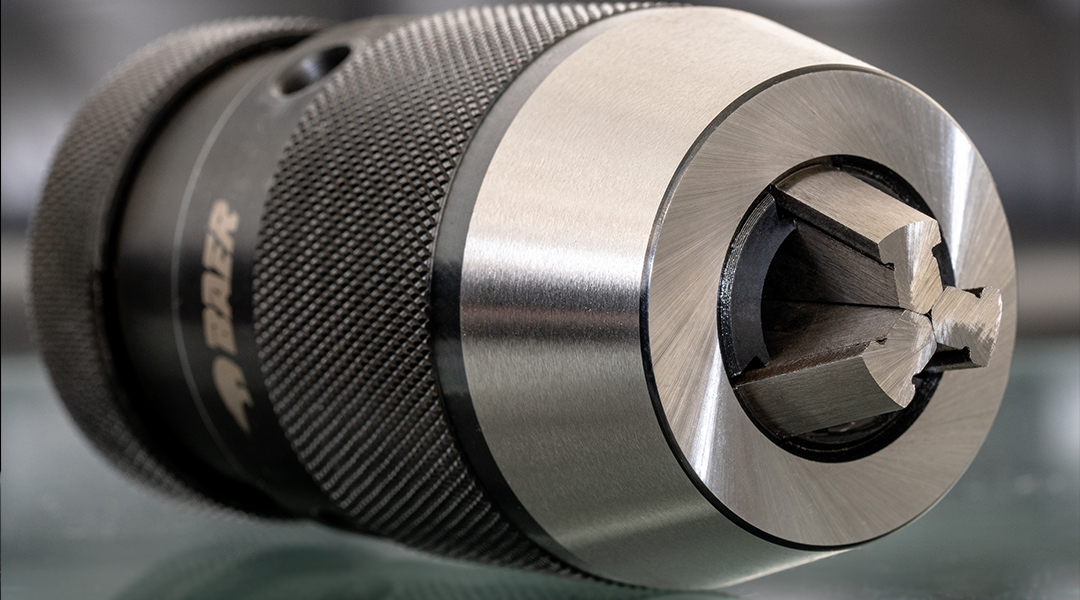

Did someone say thread? Of course, at BAER we also have the right tool for the smallest of the small. With our mini taps you can cut threads that you can hardly see with the naked eye. Get the magnifying glass out already!

Only small taps or already mini?

You probably curse from time to time because, while doing DIY or assembling furniture, you dropped a small screw and it disappeared into some crack, never to be seen again. We encounter small threads quite frequently because, for reasons of economy and aesthetics, we usually fall back on the smallest possible part with which a firm connection can be made. But at what point do we leave the control range and enter the realm of miniature threads?

Metric threads up to and including M 2.6 are considered mini threads. According to DIN, however, an even finer classification can be made. ISO metric threads with a nominal diameter of less than 1 mm have their own standard, DIN 14-2. This covers the range from M 0.30 to M 0.90 . The mini taps in these spheres are no larger than a pin.

These microscopic mini taps are not only used for all kinds of electronic items. In many other industries, components are also becoming increasingly tiny. Automotive engineering and medical technology would be at a loss without mini taps. In the hobby sector, model makers work with mini taps and use them to make the finest screw connections possible. An optician needs the mini tap for the production of spectacle frames and the watch industry is still one of the main customers of the filigree tools.

What does the small tap look like?

The mini tap has basically the same characteristics as any other screw tap - it is just very, very small. What is striking is the reinforced shank, which has a significantly larger diameter in relation to the head. This provides more stability and makes it possible to clamp the mini tap securely in the chuck in the first place.

Like conventional screw taps, mini taps often have a square shank. However, there are also variants that have a round shank. In the standard version, the tools are usually equipped with a medium gate and are suitable for blind and through holes. As with their larger relatives, however, there is a whole range of special designs for special purposes.

Small tap, big effect

In use, the mini tap can quickly turn out to be a diva. This is due to the filigree cutting pattern, which does not forgive any wobbles. In addition, the mini tap itself is a sensitive threading tool. The microscopically small diameters ensure that the risk of breakage is particularly high here. Of course, you can prevent this by buying high-quality tools from renowned manufacturers, but even these cannot reduce the risk to zero. So the utmost care is required when you put a mini tap to work.

Theoretically, you can cut a thread by hand with a mini tap. However, this requires a lot of dexterity and is not a task for beginners. In addition to a firm grip, you'll need a good eye or have to use a magnifying glass to even see what you're doing. We therefore advise the use of a machine, it always has a "steady hand" and increases the success rate immensely. Automatic lathes and tapping machines are particularly well suited for the use of mini taps.

Attention, danger of breakage! So you can enjoy your mini tap for a long time

There are a few things you should pay attention to in order to prevent the mini tap from breaking as much as possible. First of all, you can look for high breakage resistance when you buy the mini tap. In addition, it is essential that the mini tap drill is suitable for the material you want to work with. Here applies even more than usual: no experiments! You should also always handle your high-quality mini tap with care and regularly check whether the tool needs to be reground. When using your mini tap, never forget the lubricant to support fluid screwing. Also, make sure to cleanly remove the chips, which can otherwise quickly become a problem with these small dimensions.

Mini tap drill in BAER Online-Shop

No matter what you need a mini tap for - you are in good hands in the mini and nano thread category at BAER Online-Shop . Our mini taps cover a size range from M 0.3 to M 2.6. The tools have the gate form C with 2 to 3 threads and are just as suitable for blind holes as for through holes. They can be used on all easily machinable materials up to 900 N/mm² as well as unalloyed and low-alloy steels, such as mild steel, free-cutting steel or cast steel.

As a manufacturer of mini taps, we attach particular importance to producing break-proof tools. That is why we use only the best quality in the selection of raw material and use all our skills to offer precise and reliable taps even at the mini level. However, we know: an occasional breakage cannot be completely avoided. That's why you get our mini taps in sets of 10. This way you always have a replacement and can continue working directly if something does happen. You can also purchase some sizes individually.

By the way, when browsing for mini twist drills at Online-Shop, don't forget the mini twist drills for the extra small core hole drilling. And if you have any questions or suggestions, our friendly customer service will be happy to help!