Single-cut taps - practical & convertible

At first glance, the world of screw taps is clearly divided into manual and machine. Industry and series production? That only works with a powerful machine. Flexibility is more important than speed? Manual taps are the tool of choice. Both variants offer you a wealth of specially adapted tools for every type of material and even devious applications.

However, the range of screw taps doesn't stop there. There is one tool that bridges the gap between hand and machine. The single-cut tap is a hybrid of both special tools and can also serve both areas. In a flying change, so to speak, you use the single-cut tap first with the tap wrench, then with the stationary tapping machine. The all-rounder scores with advantages in both variants - but also brings with it some limitations. Reason enough to take a closer look at the versatile tool!

The best of two worlds

As a true "converter between the worlds", the single-cut tap combines features of a hand tap and a machine tap. Its defining characteristic is already in its name: The single-cut tap cuts the thread in just one step. This makes it superior to the hand tap in terms of speed and ease of use. Normally, cutting threads by hand requires at least two, often even three separate steps, each of which must be performed with a specialized drill. Add to that the time it takes to change tools, and there really shouldn't be any time pressure breathing down your neck when threading by hand.

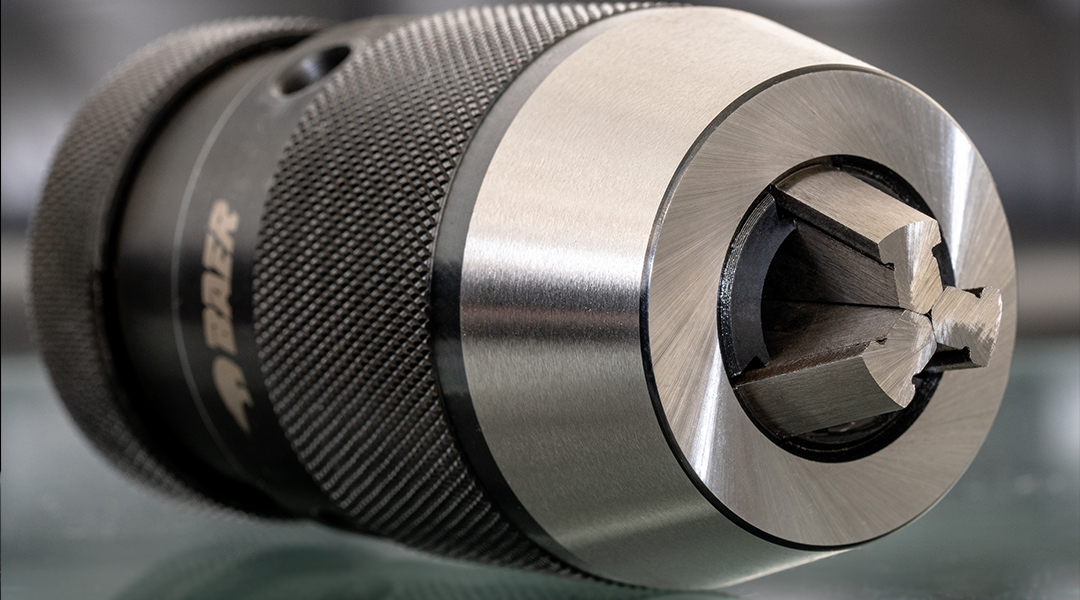

To make manual tapping possible in just one operation, the single-cut tap combines the features of the roughing tap and finishing tap from one manual tap set. This means it has a long lead-in and, at the same time, fully formed teeth that cut the full thread into the workpiece in one cut.

However, the single-cut tap is even more than just the fusion of two hand taps. It also functions under the designation "short machine tap". This already indicates that the strengths of the tool are not limited to manual use. The single-cut tap can also be clamped in a machine, thus completing the transition to a machine tap. It differs from its less versatile "big brothers" in its length. A single-cut tap is significantly shorter than a pure machine tap.

Flexible in use: This is how thread cutting works with the single-cut tap

You can operate the single-cut tap both manually and with a machine. Depending on the selected application option, you use either a holding tool or a stationary drill accordingly. First, you need to prepare the core hole in which the thread is to be cut later. Pay attention to the appropriate diameter here! Which is the right one for your desired thread size can be calculated with a formula. Tip: A practical table with the correct core hole dimensions for all common thread standards and sizes can be found at BAER Online-Shop on the product pages of our single-cut taps or you can find an overview of the most common core hole dimensions here under Service.

The core hole is created with a standard twist drill. We recommend that you then countersink it with a taper countersink before using the single-cut tap. For manual use, clamp the drill in a suitable holding tool, such as a tap wrench. Then turn the single-cut tap slowly and carefully with some pressure into the prepared hole. If you are using a floor or bench drill, it will do the work for you. In both cases, do not forget the lubricant!

Single-cut taps: these are the limitations

You already know what advantages you can expect when you buy a single-cut tap. In manual use, the work is done more quickly than when speed cutting with manual tap sets. There is no need to change tools and the thread is cut in one operation. At the same time, single-cut taps are flexible enough to be used in the machine as well.

Nevertheless, you should also be aware of the limitations before you decide to buy a single-cut tap. The screw taps have a long lead, which is only conditionally suitable for blind holes, since the thread can thus not be cut to the bottom of the hole. Since the necessary effort is not distributed among several tools, as is the case with 2- or 3-part hand tap sets, greater forces act on the single-cut tap. This can lead to faster wear or even to the drill breaking more quickly when it is set at an angle. For manual use, special hand taps are also more user-friendly and easier to operate. A certain amount of experience in the field of thread cutting is therefore an advantage when using them. If you are aware of these limitations, however, a single-cut tap is a wonderful addition to your tool inventory.

Single point taps in the Online-Shop at BAER

Whether you use it manually or in the machine, the quality of your single-cut tap plays the key role in both cases when it comes to cleanly cut threads. And that's where you've come to the right place at single-cut tap manufacturer BAER. For 40 years, we've been manufacturing threading tools with care and dedication in our family-owned business. We understand our craft and make sure that you can perform yours with tools of the highest quality. With our high-speed steel single-cutting taps, you can effortlessly machine all materials with good machinability up to 800 N/mm² as well as unalloyed and low-alloy steels.

We stock single-cut taps for all common thread standards and sizes. Even special shapes such as trapezoidal threads or photo and C-mount threads can be produced with our single-cut taps. Or use bit single-cut taps to extend the range of applications to cordless screwdrivers as well.

You can choose to buy your single-cut tap individually or as a set. This way, we make it easy for you to reorder spare parts or fill individual gaps in your tool inventory. As much as necessary, as little as possible - so you save money and only have twice what you need twice.

If you have any questions, requests or suggestions, please feel free to contact our customer service. We are happy to advise you and are there for you with any request!

Please also visit our other websites:

We cordially invite you to visit our partner sites Baercoil.com and Bohrfutter.com and to convince yourself of the quality and variety of our products. We thank you for your interest and look forward to welcoming you on our pages!