Hand taps from BAER - All important facts

You think thread cutting is only for industry or series production? Far from it! Nowadays, there are powerful tools that can also be used in manual operation. Hand taps make it possible to cut threads yourself even if you don't have any large machines available, are on the road a lot or, as a DIYer, only need a thread for a very specific project. We explain what hand taps are, how they are used and what you need to look out for when buying hand taps.

Different types of screw tap: these are the differences

If you look around in our Online-Shop, you will encounter various designations for screw taps. Each screw tap falls into one of three groups: Hand taps, machine taps, and single-cut taps.

These differ as follows:

Hand tap

Hand taps have been specially developed for manual use. A solution had to be found to apply the force required to cut a thread even without machine support. For this reason, hand taps cut the thread in three successive steps. Three different tools are required for this.

Machine tap

Machine taps are used in CNC machines or drilling machines with tapping chuck and are mainly used in industry and high volume. Supported by the power of the machine, you only need one pass to cut the full thread.

Single-cut tap

Single-cut taps are a kind of middle ground between hand and machine taps. They also cut the complete thread in just one operation, hence the name. They are suitable for both machine and manual use.

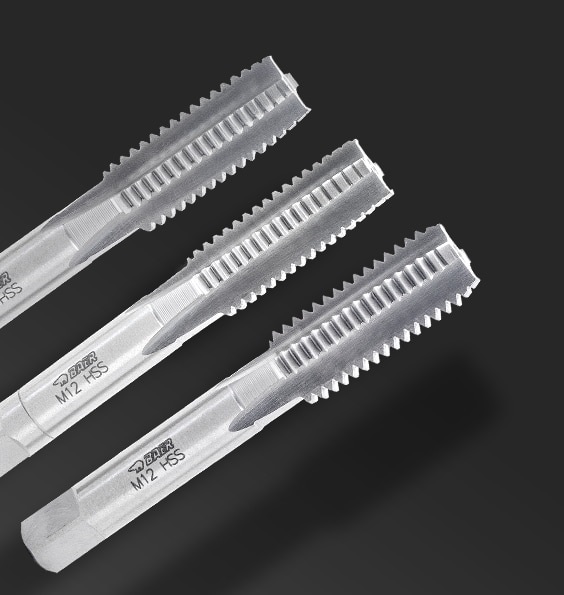

This is how a hand tap is constructed

Each hand tap ends in a square shank that allows it to be clamped into a tap wrench or tool ratchet for use. So far, so familiar. Where it gets exciting is at the other end.

The head of a hand tap has a few distinctive features:

- Center points: The head of a hand tap can be pointed or flat. Small screw taps usually have a center point so that in the manufacturing process the screw tap can be clamped between the points and a thread can be ground on the blank. Larger screw taps have a center hole at the point. However, this does not determine what type of hole the threading tool is suitable for. Because through holes and blind holes can also be cut with a pointed head, since the core hole also have a point due to the previously used twist drill. The decisive factor for a blind hole thread is the gate of a screw tap.

- Gate: Both diameter and profile reach their full expression only after a certain number of thread turns. The part before this point is called the gate. Different gate lengths result in hand taps with different properties. The finish tap of a hand tap has a short gate with form C with approx. 2 - 3 threads of gate, so that blind holes can also be cut with it.

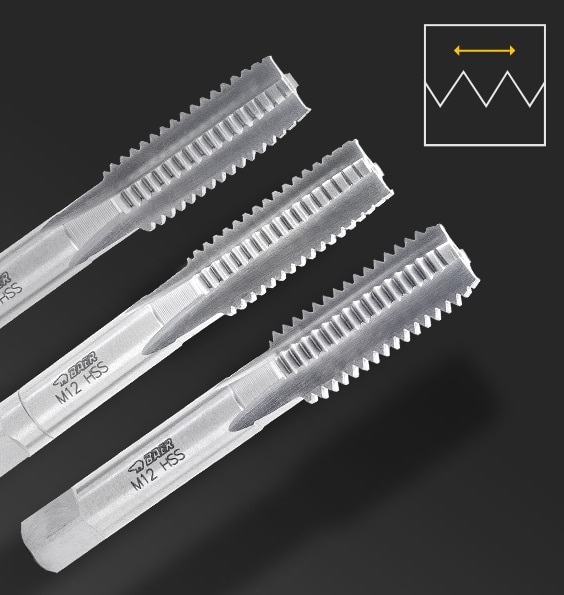

- Thread profile: The profile of the thread is created by an interaction of various dimensions that are precisely defined by standards. These include the nominal diameter, flank diameter, the pitch and the flank angle. Don't worry, for now you just need to know which standard you want to work with.

- Flutes: Hand taps have straight flutes along the entire length of the head, which allow chips to collect.

It's easier together: That's why hand taps only work as a set

In metal-cutting processes such as tapping, a great deal of force is required to remove material from materials, some of which are very strong. In order to make it possible at all to apply this force in the manual application, the load is distributed over several tools. This also reduces the stress on the individual screw taps and prevents them from breaking.

The individual tools in a hand tap set build on each other. The lead is shorter and the teeth do not reach their full extent until the last tap. For quick and reliable differentiation, the individual screw taps are marked with rings on the shank.

The following hand taps are available:

Precutter

- long gate

- Teeth incompletely pronounced

- cuts approx. 55% of the thread profile

- marked with a ring

Center cutter

- medium gate

- Teeth more pronounced

- cuts approx. 80% of the thread profile

- marked with two rings

Finishing cutter

- short gate

- Teeth completely pronounced

- cuts 100% of the thread profile

- without ring

Three hand taps are required for cutting regular threads. For fine threads with a narrower thread profile, on the other hand, only two taps are used: the pre-cutter and the finish tap. The form of the tap for fine threads corresponds to that of the center tap for standard threads.

Hand tap for regular thread

Hand tap for fine threads

The disadvantage of this division is the comparatively high time expenditure. Three separate operations, each with a tool change, require considerably more time than tapping with machine or single-cut taps. Hand taps are therefore not a solution if you want to cut many threads frequently. In these cases, it is then more worthwhile to invest in your workshop equipment in order to benefit from the advantages of machine tapping. However, for do-it-yourselfers or craftsmen for whom thread cutting is an infrequent topic or who would like to work location-independently, a hand tap set is a great option.

Buy directly from hand tap manufacturer in the BAER Online-Shop

At BAER Online-Shop you will find hand taps for every application. We carry hand tap sets not only for the metric ISO thread widely used in Europe, but also for other common standards such as the British BSW and BSF threads or the Unified National Thread s from the American region.

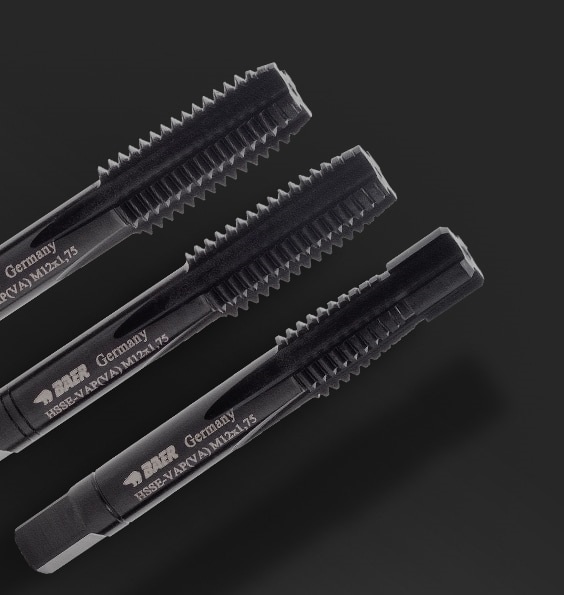

Our hand taps are made of high-speed steel (HSS), which scores with high temperature resistance and breaking strength and is very easy to grind. For hand taps for high-strength materials, we use HSSE, a high-speed steel with a particularly high cobalt content. This provides a pronounced hot hardness resistance and thus enables the machining of materials that are difficult to machine. With special cutting geometries and coatings, we then further adapt the hand taps to a specific cutting case. The oxidized surface of the vaporized hand taps is designed for machining stainless steels. With our standard design for normal application, materials with good machinability up to 900 N/mm² as well as unalloyed and low-alloyed steels such as free-cutting steels, case-hardened steels or unalloyed quenched and tempered steels can be cut excellently.

At BAER you can purchase hand taps either individually or in 2- or 3-part sets for one standard size each. In addition, we also carry extensive sets that cover your complete needs for hand taps and accessories for a range of sizes in a practical box and additionally receive the matching thread cutting dies and the required tap and holding tools. You decide what you really need and which of our products usefully complement your stock tools.

You want to buy hand taps and you need an in-depth purchase advice? Our customer service is there for you. Contact us by phone, email or via our contact form and let us help you competently!

Please also visit our other websites:

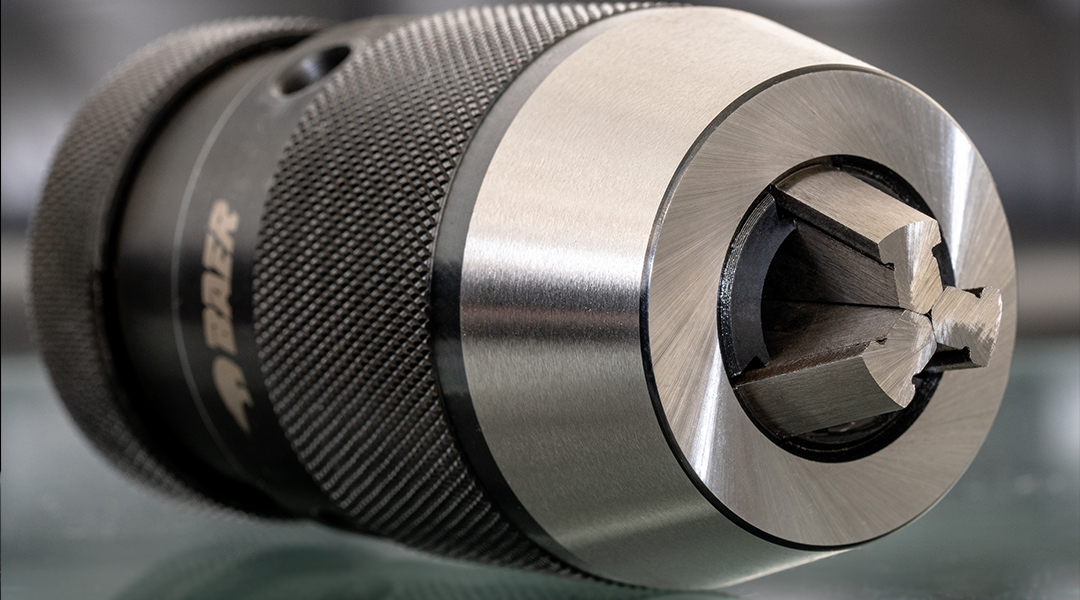

Also visit our websites Baercoil.com and Bohrfutter.com and discover more first-class products! At Baercoil.com you can learn all about our high-quality thread inserts and thread repair systems. At Bohrfutter.com you can expect a large selection of CNC drill chucks, precision quick-action drill chucks and much more. Immerse yourself in quality, variety and fair prices. And if you have any questions or requests, our first-class customer service is always happy to help. Take a look right now!